GREENS AND STREAMS BLOG

Tying at Coren's Rod and Reel - March 28th

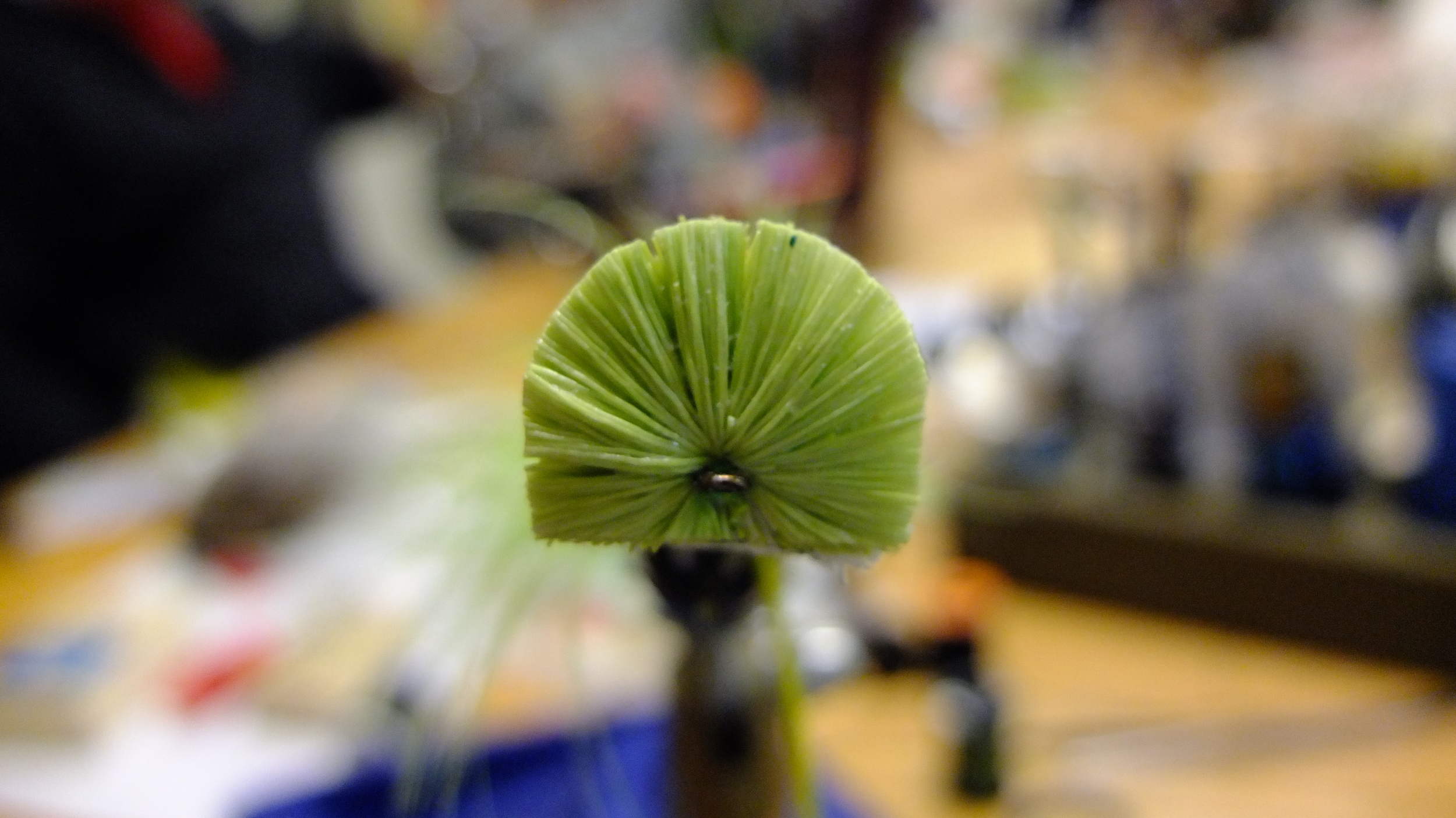

Cory Gale - Art of Spinning, Stacking, Packing and Trimming Deer Hair

Cory Gale is a friend of mine and we have tied flies together for over fifteen years. I remember when he first came into the fly shop where I was working and the Bass Buggers were sitting down to a tying session. He came to watch. I have a rule, it has been a rule for a long time – No Watching!

So he sat and tied. He wasn’t very good but he was earnest. And as he’d say, “I was hooked.” Cory continued to improve and was very interested in deer hair bugs. Like anyone seeking to improve, he found a teacher and took lessons from the master: Chris Helms. From his sessions with Chris, Cory continued to improve and his flies, as you can see from the photos, are what we all aspire to, tight, well packed and durable hair bugs. Beautiful can also be applied to them.

Cory has from time to time, given me a fly or two and yes, I have fished them. I know, usually most people decorate their boxes with hair poppers and divers but when they hit the water, they pull out the foam ones . But hair bugs are great in the water, they leave a lot of bubbles, are usually light and cast well and besides, they just look cool. And tying deer hair is a skill set that anyone wanting to tie more than just a woolly bugger or clouser minnow should learn.

And now is your chance. At the end of the month, Saturday, March 28th at 9:00 at Coren’s Rod and Reel, 6001 N Nina Ave, Chicago, IL 60631 · (773) 631-5202, you can take a free deer hair seminar with Cory.

You have to have your own vise and tools and a spool of GSP. There will be some available for purchase but I suggest you get a spool and bring it along. Also if you have deer hair suitable for spinning, bring that as well. While this is a free seminar, I would ask that at the end of it you toss a couple of bucks into the kitty for Cory as he puts a lot of time, effort as well as supplying materials for this seminar.

Chris Helms passed away in November of 2014 but his student, Cory, continues the tradition of tying deer hair bugs. I am certain that Chris would say of Cory, “Well done my student, well done.”

So if you’re interested in spinning, stacking, packing and trimming deer hair to make poppers, sliders, and all kinds of interestingly shaped flies. Then come this Saturday. Space is somewhat limited so you might want to bring a folding chair.

See you there!

Here’s that info one more time:

Location: Coren’s Rod and Reel, 6001 N Nina Ave, Chicago, IL 60631

Time and Date: Saturday, March 28th at 9:00

Phone: (773) 631-5202

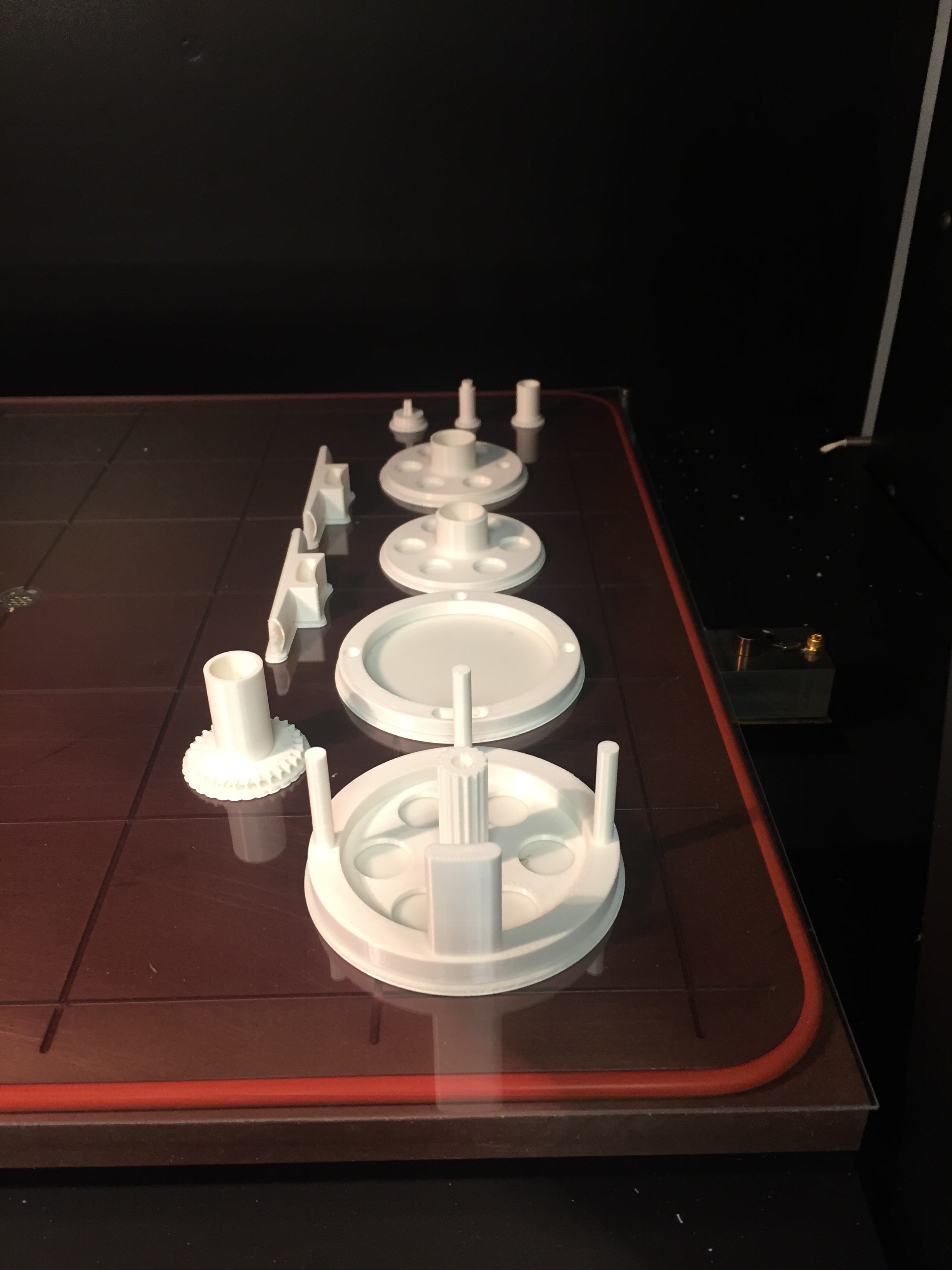

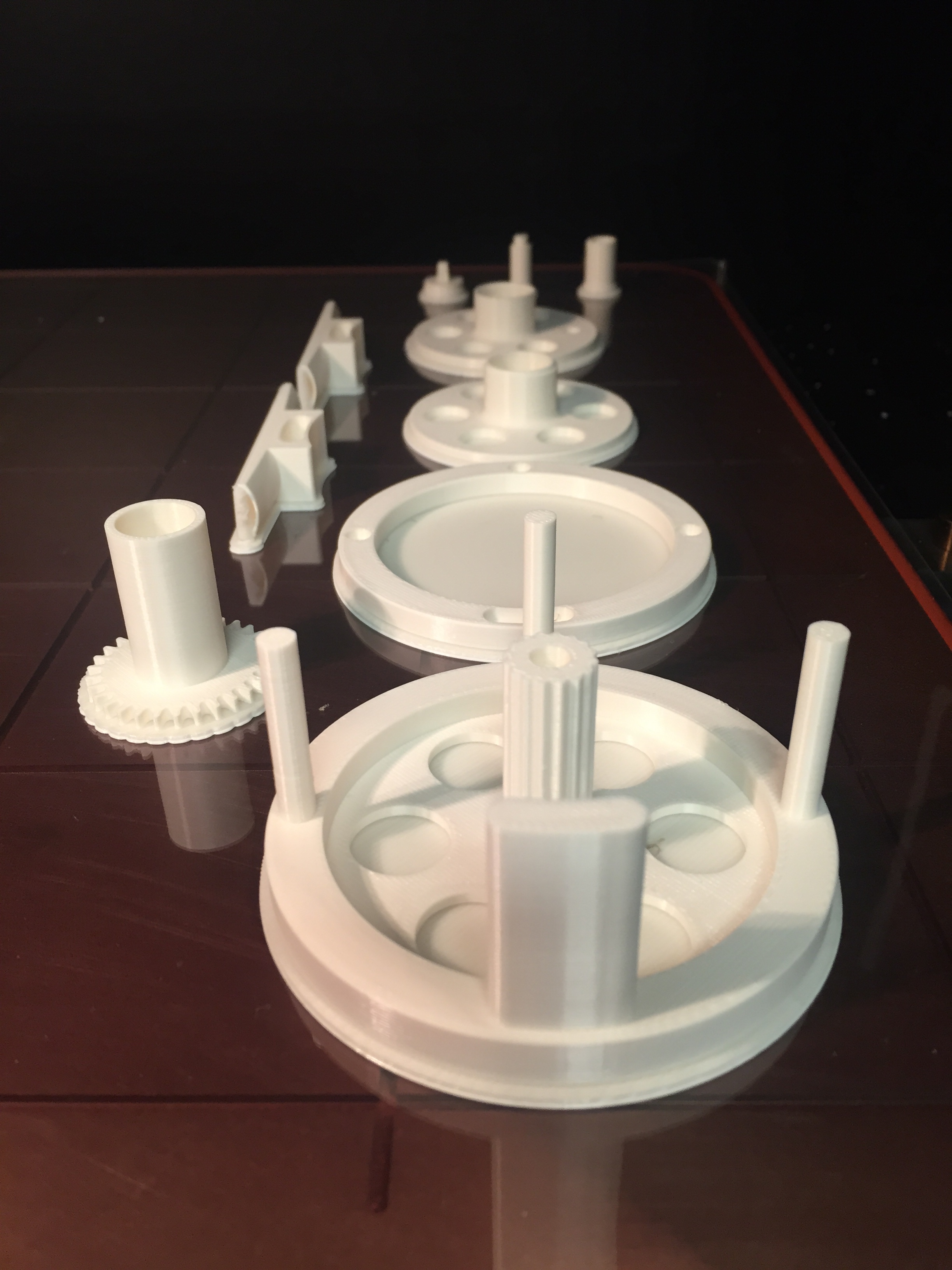

Side Projects - 3D Printed Reel

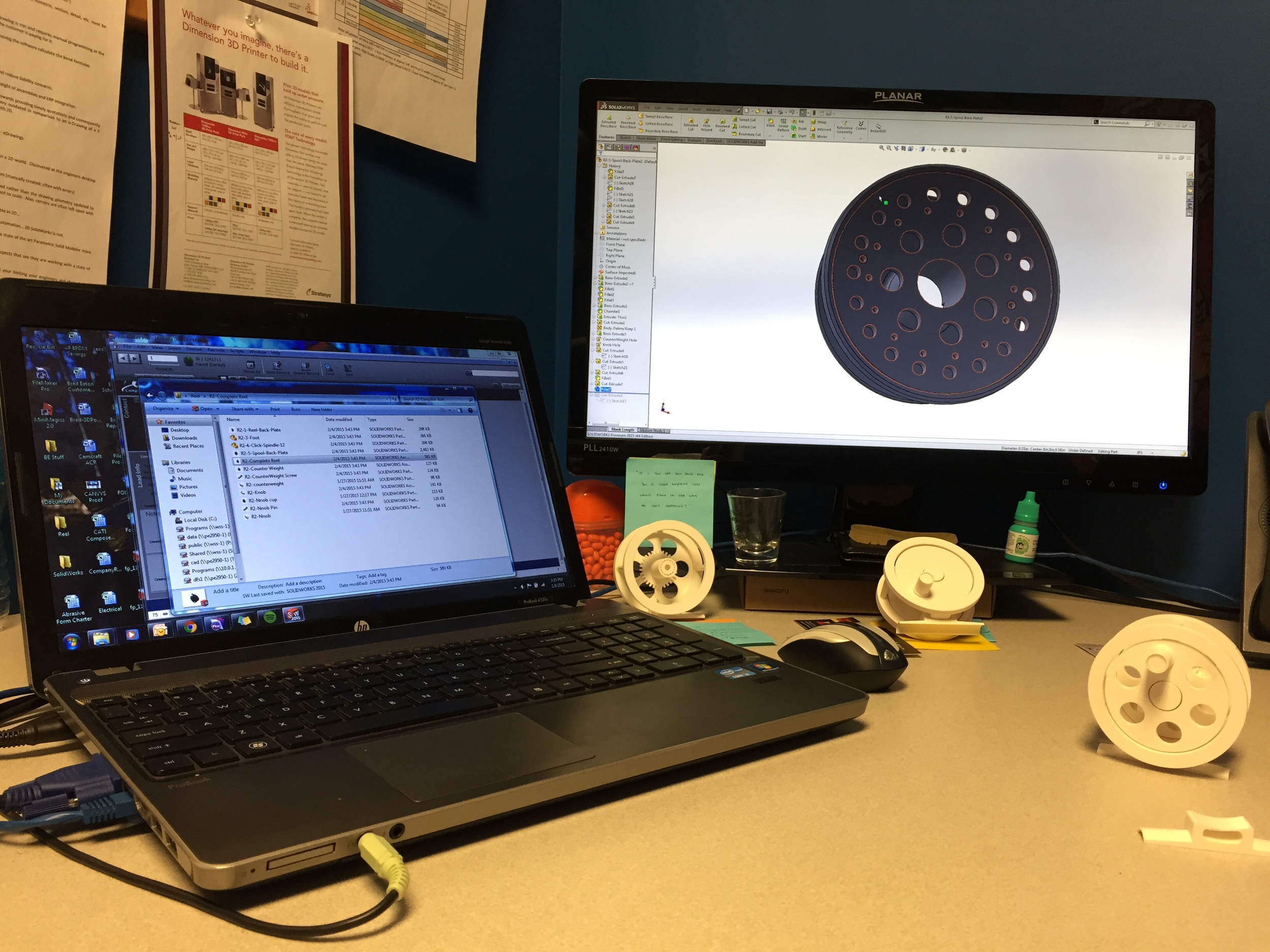

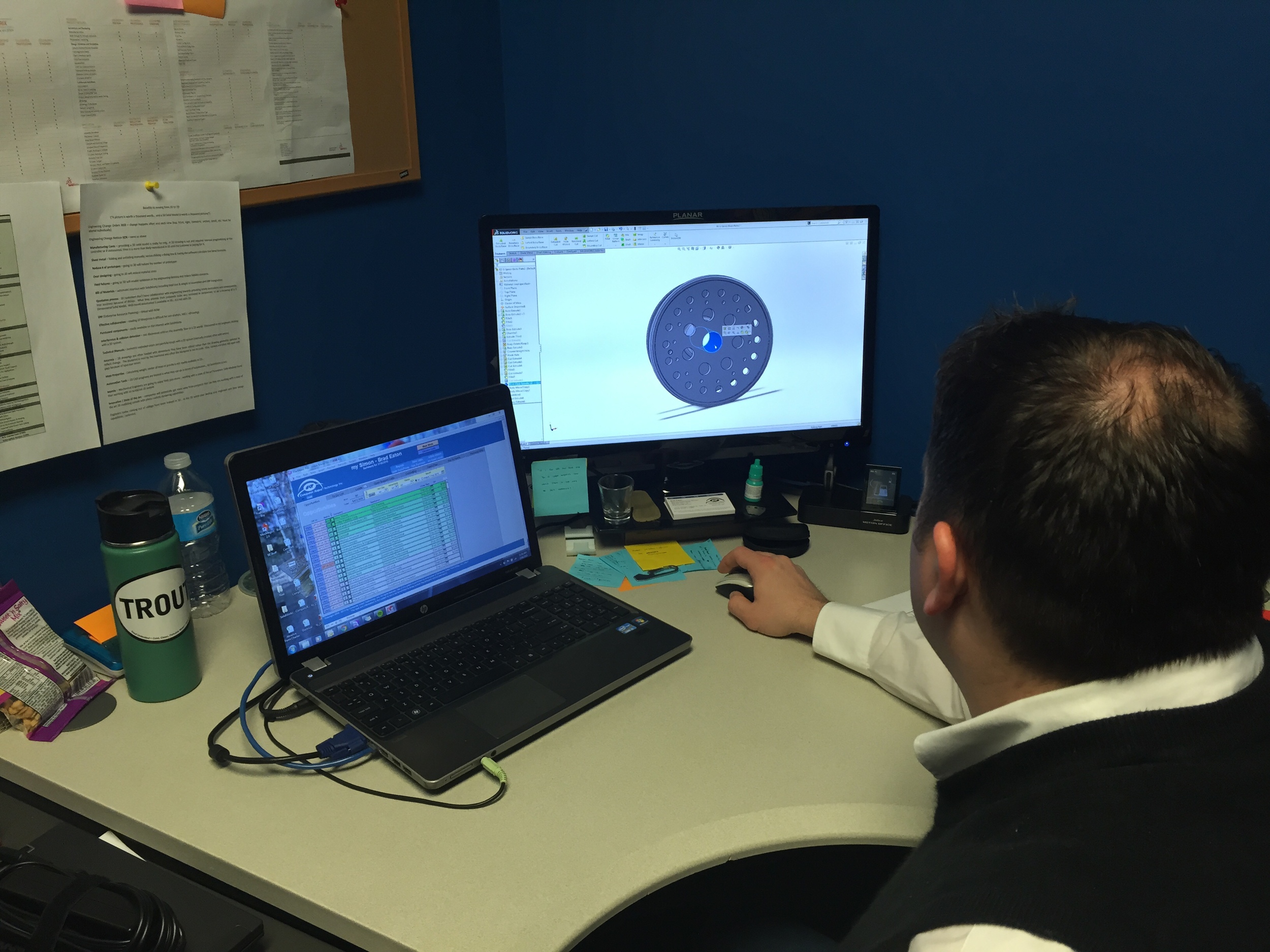

So if you've been following us here at T&T for any length of time, you've surely realized I work for an organization that partners with manufacturing companies and we sell software and hardware that allows them to save time and money developing and producing their products. These boil down to a CAD (computer aided design) tool named SolidWorks, and 3D printers under the Stratasys brand.

If you ask my wife, she'd tell you I'm always trying to think of my next "project". Whether it be another rod to build, blog to start, few dozen flies to tie, I've always got my fingers doing something, and lately it seems the projects are starting to escalate. Now they're things like a tear drop trailer, truck top tent, starting a production company - not really small projects, and in reality, mostly pipe dreams. But one that always stays close to the top is designing and printing my own fly reels.

Seeing so many amazing designs in places like The Classic Fly Rod Forums - Rod and Reel Makers Forum, I wanted to be able to take what I was doing on a daily basis for my job, and roll it in to making my own versions of what I was seeing online. So I set out to figuring out how to craft my design and started working on learning SolidWorks. This is where things came to an abrupt halt. Finding the time to teach yourself a tool that, though easy to use, requires dedication and I just couldn't find the time to break away from my job to attend one of our training classes. Enter Michael Hackney and the Eclectic Angler.

Michael worked for a year before he perfected a reel that was easy to print, cost effective (read inexpensive to produce), and had a great look to it. We traded emails back and forth a while back but again, my inability to focus on the task at hand, made this project falter. With some exposure from the likes of Field and Stream, I realized that Michael had made the files available for download, giving me the perfect starting point. All the work Michael did perfecting the design and getting the components just right, led to a great little click pawl reel.

You can learn more about Mike and his reels by visiting the Eclectic Angler.

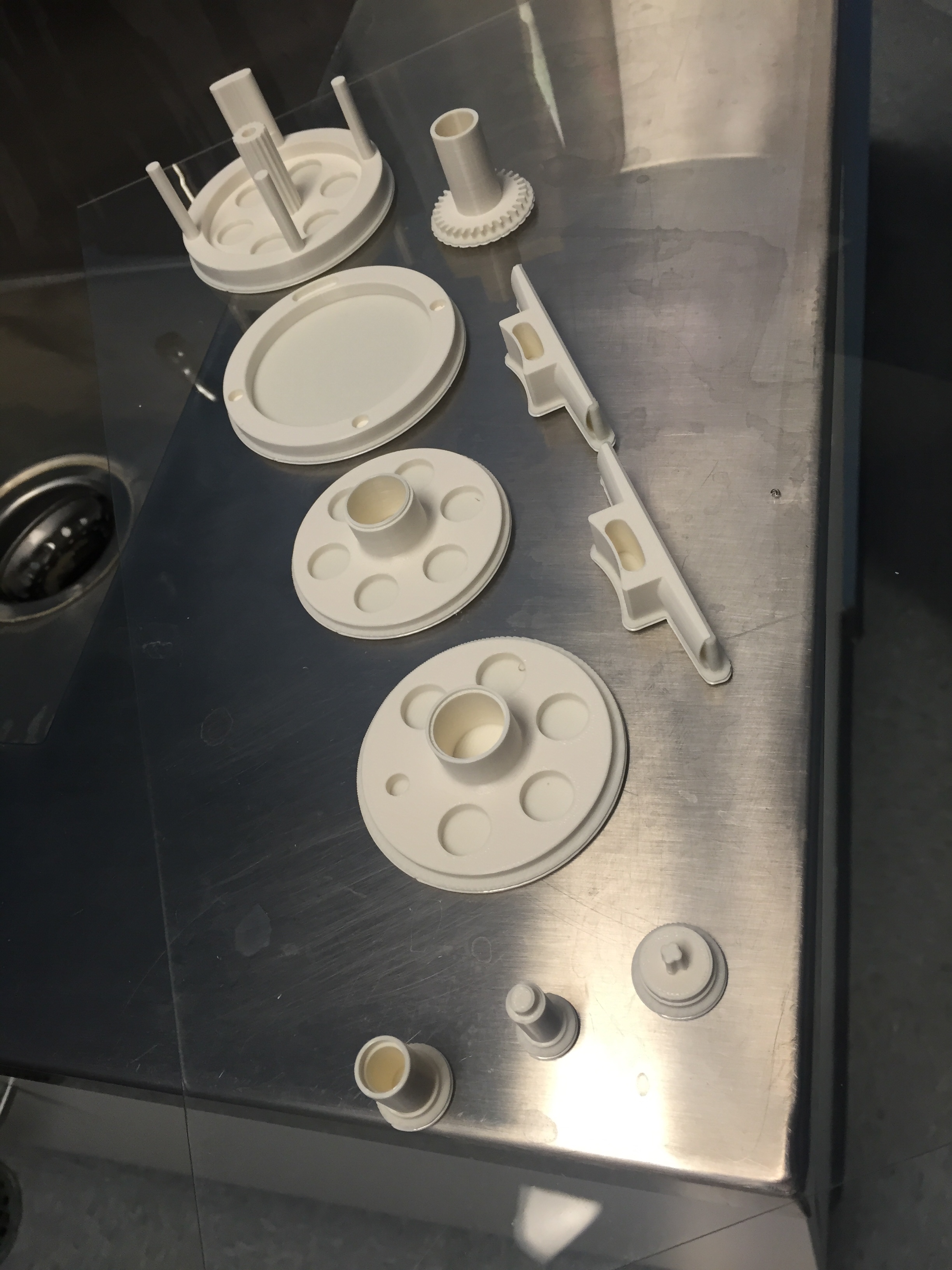

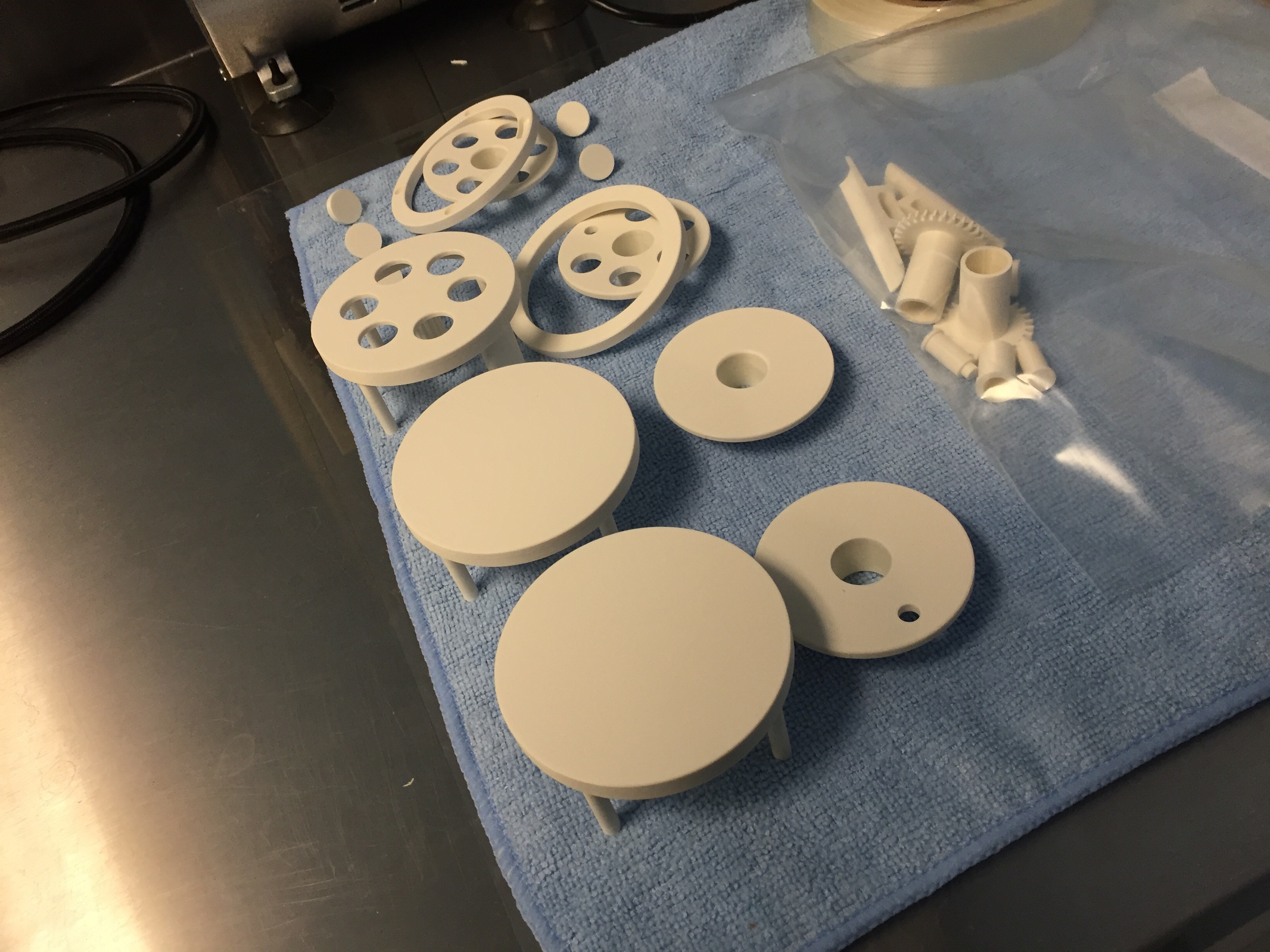

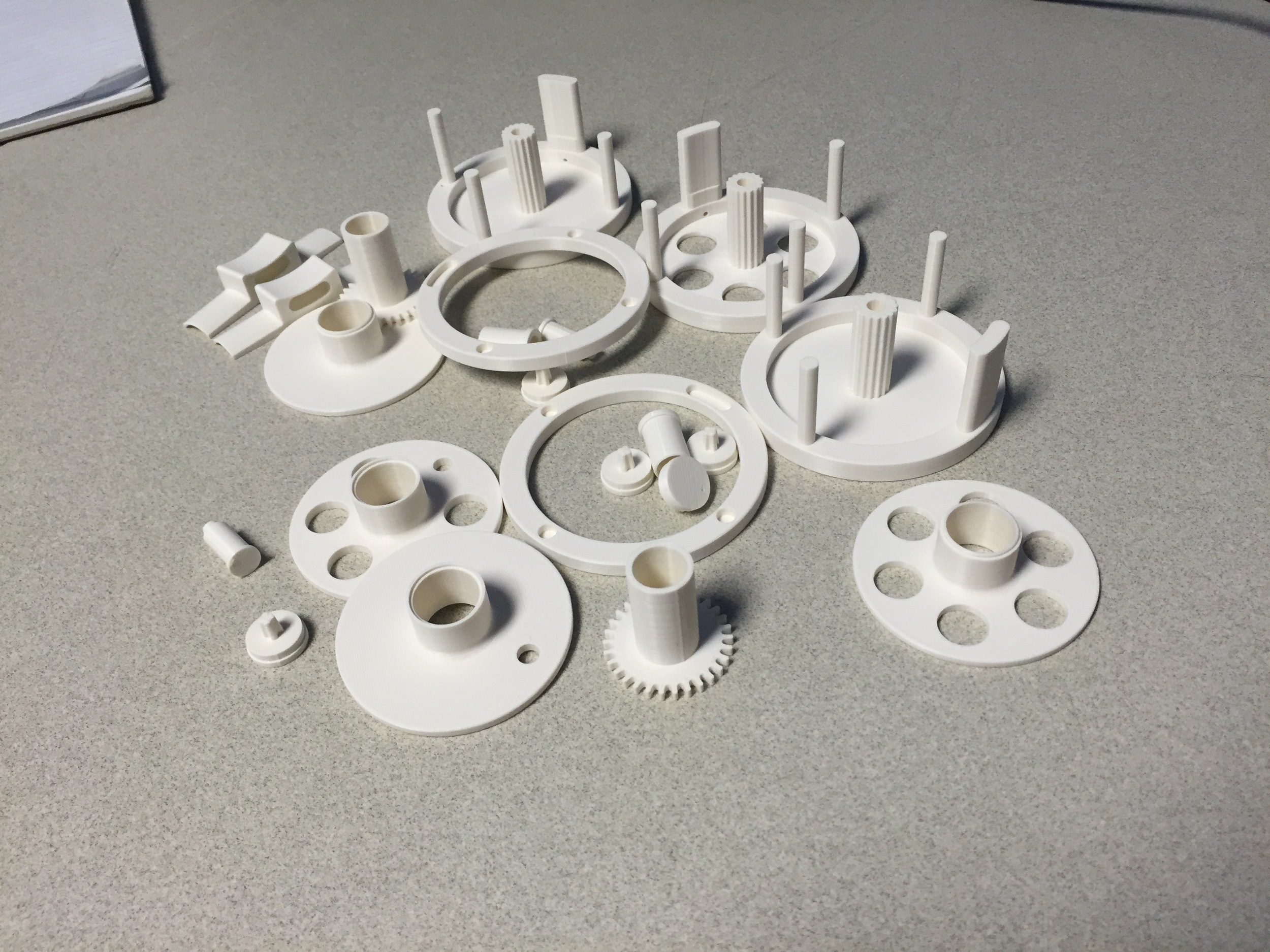

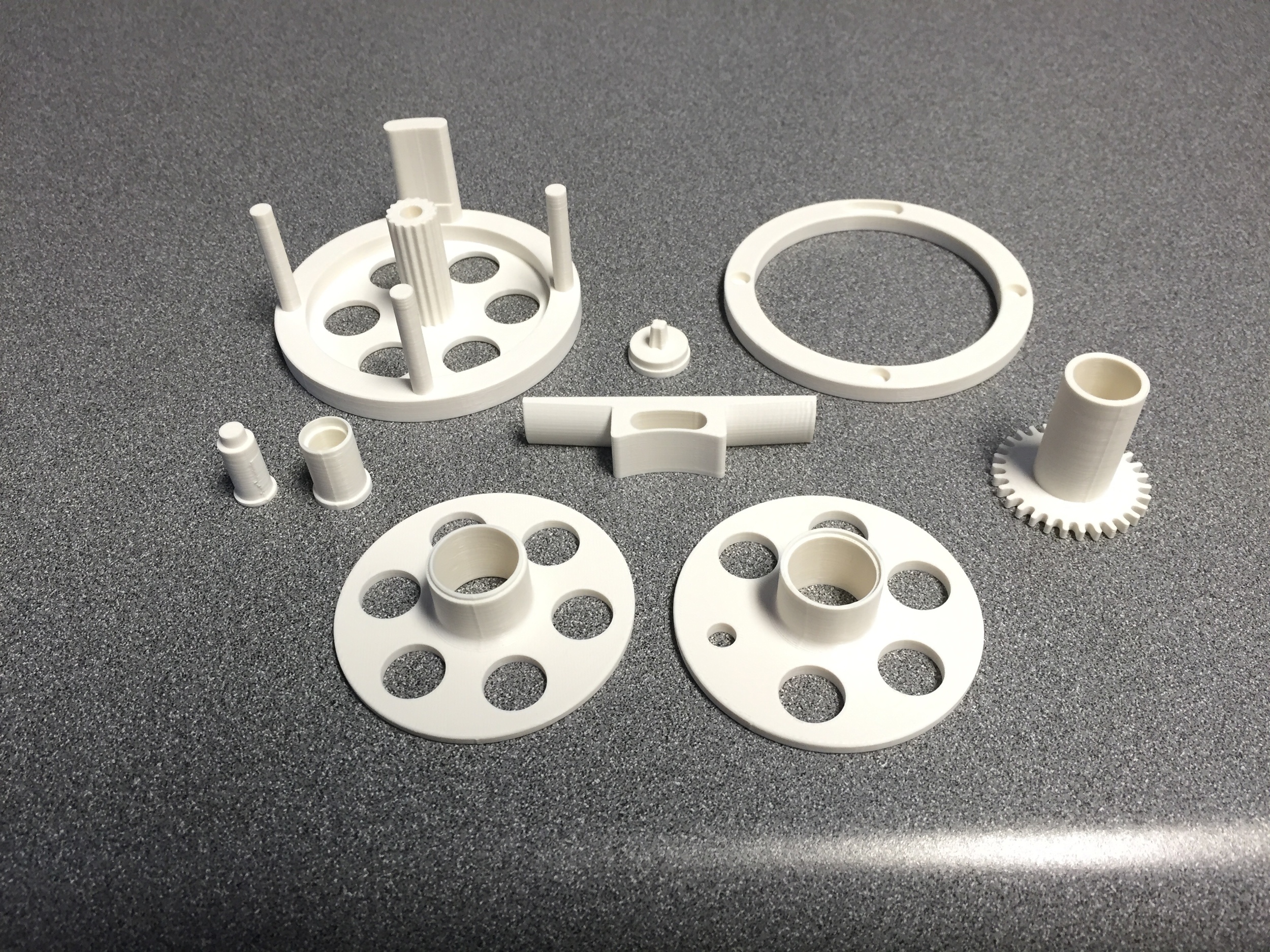

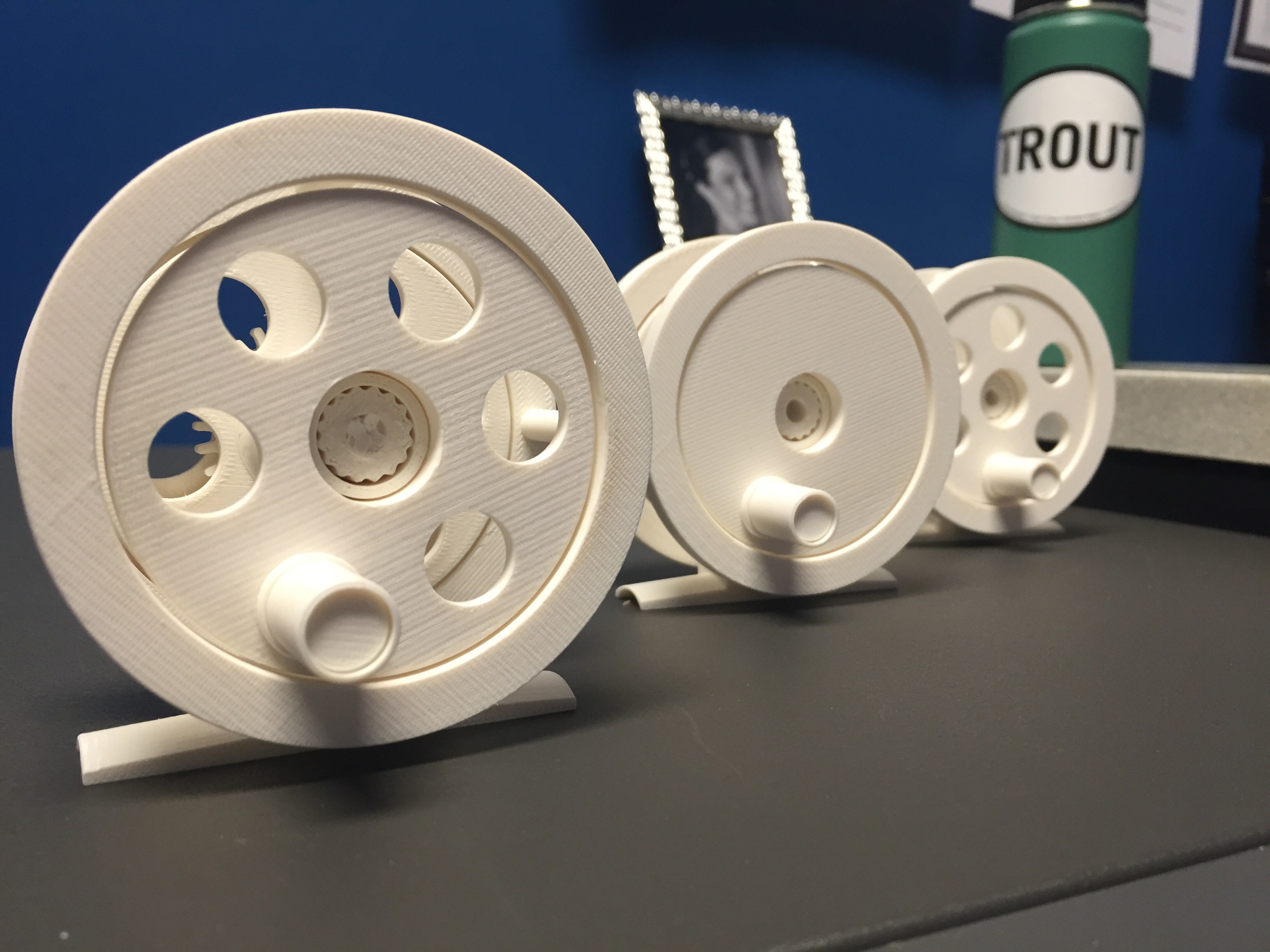

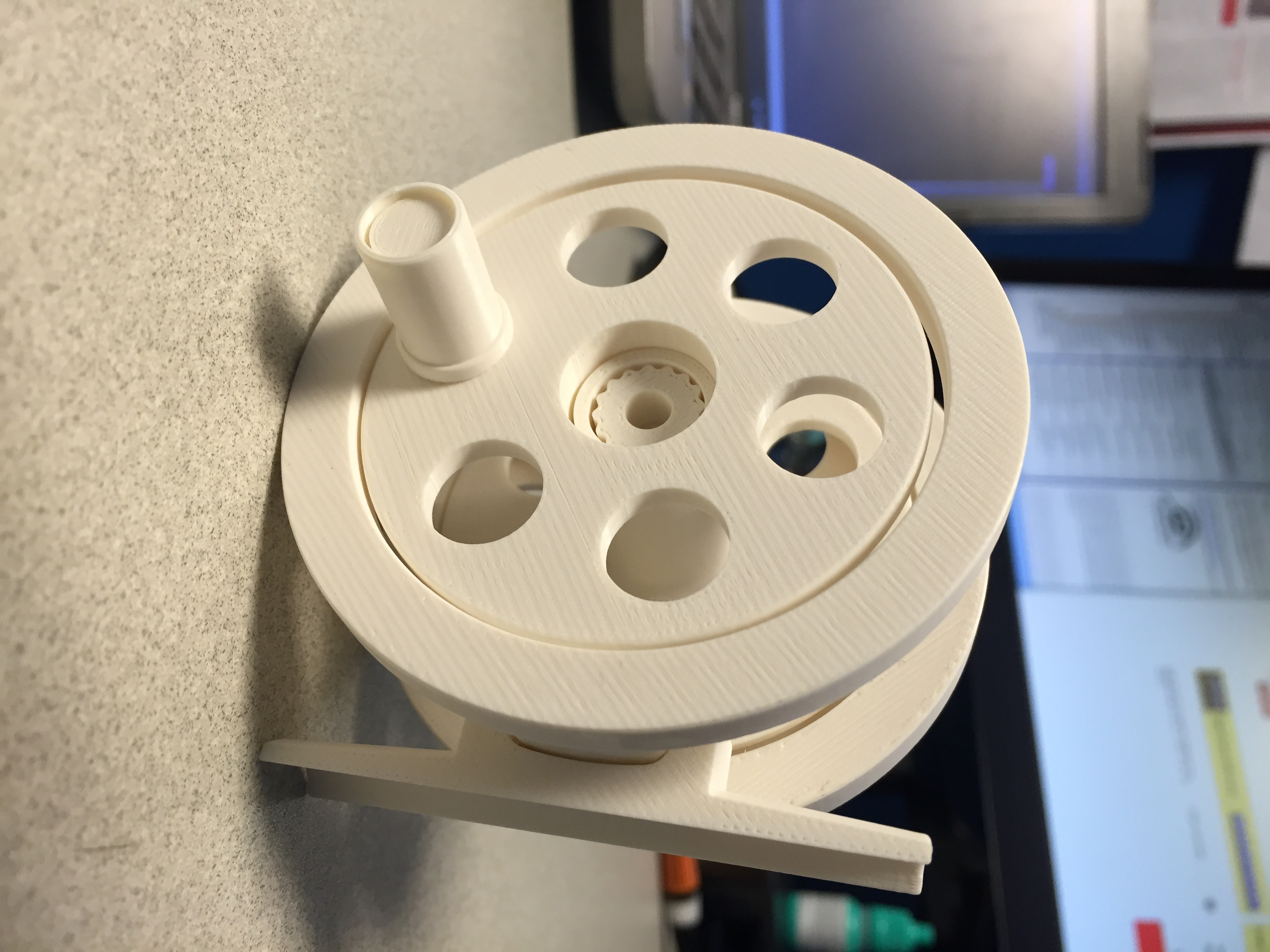

My plan is/was to have a couple of different versions and want to include both of the different technologies, from the 3D printing standpoint, that we offer. So for the first reel, we took the easy route and used Mike's reel design, processed the files for the layer thickness we wanted (.0050"), and laid it out on the print bed. Total print time would be six hours from start to finish. This meant we could have cleaned, finished reels, in about eight hours total, including the required post processing. We used a standard ABS plastic, similar to what's used in most injection molding processes.

The way the reel is built is call FDM or fused deposition modeling. To make a good comparison, imagine taking a hot glue gun, and taking weed wacker cord filament, and push it through the tip of the hot glue gun. The plastic will melt as it's extruded from the tip, and the layers will adhere to each other. The tip will trace out wherever material needs to be present, leaving a finished part. (see illustration) Depending on the machine you're using to produce the parts, you can determine how thick each layer is, yielding faster build times or a part with better resolution or greater accuracy.

The reel itself is a total of eight pieces, with two pieces making up the spool. Michael recommended using a small nylon filament extrusion for the clicker mechanism, which we found is definitely the way to go. That is after we tried about a dozen other options, all failing quickly, I finally caved and ordered the filament from Amazon. Sometimes I just want to find my own way, but will never hesitate relenting to what's proven.

I'm working on fine tuning the design for our next version, which will use a different 3D printing technology and likely mix in some actual machined components. Figuring out a click pawl mechanism and sourcing some components has prolonged the design process a bit. I'm finding that trying to design something around sourced components can be tougher than expected. I hope to have some renderings done soon and will post some more updates as the project progresses. I'm trying to channel a bit of Bogdan with some of the tradition the Hardy's. With the ability to make quick changes, I'd like to have a few ideas to play with.

Keep your eyes peeled for updates and if you have any questions, or want to learn, please don't hesitate to comment or send us a note!

Spring Fishing - Black Earth Angling Co.

As reports roll in for the first few weeks of the Early Season in Wisconsin, it sounds like the warm up has left the banks free of snow and the waters a bit up. The perfect way to start, what I hope, will shape up to be a great trout fishing season and a great fishing season overall.

For me, getting back on my feet is becoming more of a reality, as I start to take the twig that's become of my right leg, and get it back in shape. So as I kick back and enjoy some quality time with the Mrs., I thought I'd share some reports from guys out there and making early season a success.

Kyle Zempel leads Black Earth Angling Co. and is a not only a great fisherman but also quite the photographer. I've had the chance to be on the water with him a handful of times and he's knowledgeable and a hell of a fisherman. He's the only guy I've ever see pull 40+" of trout out of a single run in four casts. If you're looking for a day out in the Driftless, or a day you'll never forget on the Lower Wisconsin, give him a call. You won't regret it. Plus, rumor has it, they may have just picked up a pasture raised Berkshire hog to be incorporated in to shore lunches.

Until then, I'm counting down the days!